small engine repair manual

Welcome to the world of small engine repair! These manuals are essential guides for DIYers and professionals, covering maintenance, troubleshooting, and detailed repair procedures for engines from 5.5 HP to 20 HP. Packed with step-by-step instructions and expert advice, they empower users to keep equipment running smoothly and efficiently. Whether you’re a beginner or an experienced technician, these resources provide comprehensive support for small engine care and restoration. Start your journey to mastering small engine repair with confidence!

1.1 Purpose and Scope of the Manual

This manual is designed to provide comprehensive guidance for repairing and maintaining small engines, ensuring optimal performance and longevity. It covers a wide range of topics, from basic troubleshooting to advanced repair techniques, tailored for both professionals and DIY enthusiasts. The manual emphasizes safety, proper diagnostic procedures, and step-by-step instructions for common maintenance tasks.

By following the guidelines outlined in this manual, users will gain the knowledge and confidence to handle various small engine repairs effectively. It serves as a hands-on resource, ensuring that repairs are conducted safely and efficiently, while also promoting a deeper understanding of engine functionality and care.

1.2 Target Audience

This manual is intended for a diverse range of users, including small engine enthusiasts, DIYers, professional mechanics, and students. It serves as a practical guide for individuals seeking to repair, maintain, or understand small engines. Whether you are a novice looking to perform basic maintenance or an experienced technician diagnosing complex issues, this manual provides clear, detailed instructions. It is also a valuable resource for educational purposes, offering insights into engine operation and repair principles. The content is designed to be accessible, ensuring that all users can benefit from its comprehensive coverage of small engine repair and maintenance.

1.3 Overview of Covered Engines

This manual covers a wide range of small engines, including 2-stroke and 4-stroke gasoline engines, as well as small diesel engines. These engines are commonly found in lawn mowers, generators, pressure washers, and other small equipment. The manual focuses on engines with displacements typically ranging from 2 to 25 horsepower, making it relevant for both hobbyists and professionals. Specific attention is given to popular brands such as Briggs & Stratton, Honda, and Kawasaki. Additionally, the guide addresses engines used in portable and stationary applications, ensuring a comprehensive understanding of fuel types, ignition systems, and operational principles.

Understanding Small Engines

This section provides foundational knowledge about small engines, including their types, applications, and basic operation principles. It helps users understand essential concepts for successful repairs.

2.1 Types of Small Engines

Small engines are categorized into types based on their operation and design. The most common are two-stroke and four-stroke engines, differing in how they complete a power cycle. Two-stroke engines are simpler, lighter, and used in portable tools like leaf blowers. Four-stroke engines are more efficient, with applications in lawn mowers and generators. Additionally, diesel engines are known for their torque and fuel efficiency, often used in industrial equipment. Electric motors, while not combustion engines, are included for their role in hybrid or electric small engine systems. Each type has unique characteristics, applications, and maintenance requirements.

2.2 Basic Components of a Small Engine

A small engine consists of several key components essential for its operation. The cylinders house the pistons, where combustion occurs. The pistons convert the explosive force of combustion into linear motion, which is then transformed into rotational energy by the crankshaft. The intake and exhaust manifolds manage the flow of air-fuel mixture into the engine and exhaust gases out. The carburetor mixes air and fuel, while the ignition system, including spark plugs, initiates combustion. Cooling systems, either air or liquid-based, prevent overheating. The fuel system delivers fuel, and the muffler reduces noise and filters exhaust gases.

2.3 Engine Terminology and Definitions

Understanding engine terminology is crucial for effective repair work. Key terms include combustion chamber (where fuel is burned to produce power), piston stroke (the movement of the piston inside the cylinder), and crankshaft (converts piston motion into rotational energy). Intake and exhaust valves control airflow and exhaust gases. Timing refers to the synchronization of valve openings with piston movement. RPM (revolutions per minute) measures engine speed, while torque indicates rotational force. These terms are essential for diagnosing and repairing small engines effectively.

Safety Precautions and Guidelines

Always wear protective gear like gloves and goggles. Ensure proper ventilation and avoid fuel spills. Use tools correctly and consult the manual for specific safety guidelines.

3.1 General Safety Tips

Always wear protective gear, including gloves and safety goggles, to prevent injuries. Ensure the workspace is well-ventilated to avoid inhaling harmful fumes. Disconnect the spark plug wire before starting repairs to prevent accidental engine start-ups. Use tools correctly and avoid damaged or worn-out equipment. Keep flammable materials away from the work area. Never smoke or use open flames near fuel or ignition sources. Follow the manufacturer’s instructions for handling chemicals and fuels. Maintain a clean and organized workspace to reduce tripping hazards. Regularly inspect tools and equipment for damage. Familiarize yourself with emergency procedures, such as fire extinguisher locations and first aid kits.

3.2 Hazard Warnings and Precautions

Be aware of potential hazards such as fuel spills, electrical shocks, and rotating parts. Always disconnect the spark plug wire before servicing to prevent sudden engine start-ups. Keep fuel and ignition sources apart to avoid fires. Avoid over-tightening or stripping threads, as this can lead to engine damage. Never operate the engine in enclosed spaces due to carbon monoxide risks. Be cautious of hot engine components, such as exhaust systems and cylinders, which can cause burns. Use jack stands for lifting engines to prevent accidents. Consult the manual for specific warnings related to your engine model and adhere to all precautions.

3.3 Protective Equipment and Practices

Always wear safety glasses or goggles to protect your eyes from debris. Use gloves to prevent cuts and abrasions when handling sharp or rough components. Steel-toe boots are recommended to safeguard feet from heavy tools or falling parts. Keep long sleeves and pants to avoid skin exposure to hot surfaces or sharp edges. Ensure good ventilation in your workspace to avoid inhaling fumes from fuels or chemicals. Use a well-lit area to improve visibility and reduce accident risks. Avoid loose clothing or jewelry that could get caught in moving parts. Keep a fire extinguisher nearby when working with flammable materials.

Essential Tools and Equipment

Essential tools include wrenches, screwdrivers, pliers, and sockets. Specialized tools like compression gauges and spark testers are vital for diagnostics. A multimeter aids in electrical system checks.

4.1 Basic Hand Tools

Essential hand tools for small engine repair include adjustable wrenches, socket sets, screwdrivers (both Phillips and flathead), pliers (needle-nose and slip-joint), and punches. A torque wrench ensures proper bolt tightening. Screwdriver sets should include various sizes to fit engine screws. Pliers are useful for gripping small parts, while punches help with piston pin removal. A set of metric and SAE sockets covers most bolt sizes. Durable toolboxes or organizers keep tools tidy. High-quality tools reduce the risk of rounding bolts or damaging components. Proper tool maintenance, such as cleaning and lubricating moving parts, extends their lifespan. Always choose tools that fit comfortably in your hand for precision and control.

4.2 Specialized Tools for Small Engines

Specialized tools for small engine repair are essential for specific tasks. A piston ring compressor is necessary for engine rebuilding, while a cylinder hone tool ensures proper surface finish. Carburetor adjustment tools, like jet cleaners and adjustment screws, are vital for tuning. A compression test kit helps diagnose engine issues, and an ignition timing light ensures accurate spark timing. Crankshaft locking tools prevent movement during repairs, and a valve spring compressor aids in cylinder head work. These tools are often model-specific, so consulting the engine’s service manual is crucial for selecting the correct ones. They enhance precision and efficiency in complex repairs.

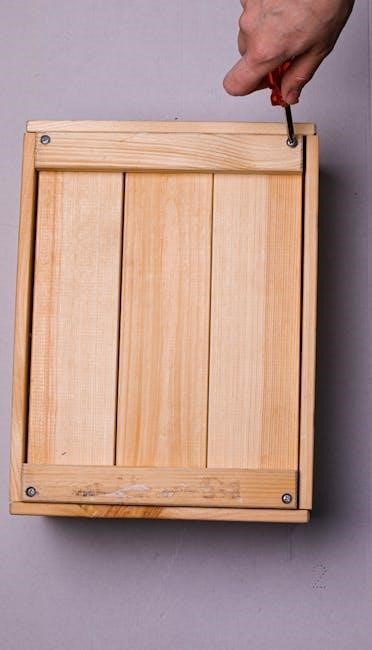

4.3 Workshop Setup and Organization

A well-organized workshop is crucial for efficient small engine repairs. Start with a sturdy workbench equipped with a vice to secure engines. Ensure proper lighting with overhead and task lights. Install storage solutions like cabinets, drawers, and bins to keep tools and parts tidy. Open shelves can store frequently used items, while labeled containers help manage small components. A pegboard for hanging tools adds flexibility. Designate specific zones for disassembly, cleaning, and reassembly to streamline workflows. Clearly label all storage areas for quick access. A clean, organized workspace reduces errors and saves time, making repairs safer and more effective.

Troubleshooting Common Issues

Troubleshooting small engine issues involves identifying symptoms, diagnosing root causes, and applying repair techniques. Common problems include faulty ignition, carburetor malfunctions, and fuel system blockages. Always refer to diagnostic guides and manufacturer recommendations for accurate solutions, ensuring safety and efficiency in repairs. Proper tools and a systematic approach are essential for resolving issues effectively.

5.1 Identifying Common Problems

Small engine issues often manifest as engine failure to start, poor performance, or unusual noises. Common problems include faulty spark plugs, clogged air filters, or blocked fuel lines. Overheating, vibration, or excessive smoke are also indicators of potential issues. Routine maintenance can help identify these problems early. Always check for loose connections, worn belts, or damaged components. Diagnostic tools like spark testers and compression gauges can aid in pinpointing the root cause. Refer to troubleshooting charts or manuals for specific symptoms and solutions. Identifying the problem accurately is the first step toward effective repairs and ensuring optimal engine performance.

5.2 Diagnostic Techniques

Diagnostic techniques for small engines involve systematic approaches to identify faults. Start with a visual inspection to check for obvious damage, leaks, or wear. Use tools like spark testers to verify ignition systems and compression gauges to assess cylinder pressure. Multimeters can measure battery voltage and circuit continuity. Listen for unusual sounds, such as knocking or grinding, which may indicate internal issues. Perform test runs under load to observe performance. Consult troubleshooting charts or fault codes to narrow down potential causes. These methods help isolate problems efficiently, ensuring accurate repairs and minimizing downtime. Regular practice improves diagnostic accuracy and speed.

5.3 Tools and Resources for Troubleshooting

Essential tools for small engine troubleshooting include multimeters, compression gauges, spark testers, and fuel pressure testers. These tools help identify issues like faulty ignition systems or low compression. Resources such as service manuals, wiring diagrams, and online forums provide detailed repair information. Diagnostic software for specific engine models can also be useful. Keep a well-organized toolbox and ensure all equipment is calibrated. Reference charts and troubleshooting guides from manufacturers are invaluable for pinpointing problems. Staying updated with the latest tools and resources enhances diagnostic accuracy and efficiency, ensuring repairs are completed effectively and safely.

Routine Maintenance and Service

Routine maintenance ensures small engines run efficiently and prolongs their lifespan. Regular inspections, oil changes, and filter cleaning prevent issues and maintain optimal performance over time.

6.1 Importance of Regular Maintenance

Regular maintenance is crucial for ensuring small engines operate efficiently and reliably. It prevents wear and tear, reduces the risk of unexpected breakdowns, and extends the engine’s lifespan. By following a routine maintenance schedule, users can identify and address potential issues early, saving time and money. Proper maintenance also improves fuel efficiency, reduces emissions, and ensures optimal performance. Neglecting maintenance can lead to costly repairs and downtime. Consistent upkeep helps maintain the engine’s power output and ensures it runs smoothly under various conditions. Always refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to your engine type and usage.

6.2 Oil and Filter Changes

Regular oil and filter changes are essential for maintaining the health and performance of small engines. Engine oil lubricates moving parts, prevents overheating, and removes contaminants. The frequency of oil changes depends on usage, but most manufacturers recommend changing the oil every 50 to 100 hours of operation. Always use the oil type specified in the manual to ensure compatibility. When changing the oil, drain it properly and dispose of it responsibly. Replace the oil filter with a new one of the correct type to maintain engine efficiency. Keep track of oil change intervals to avoid neglecting this critical maintenance task.

6.3 Air Filter Cleaning and Replacement

Air filters are crucial for preventing dust and debris from entering the engine, ensuring optimal performance. Clean or replace the air filter as recommended by the manufacturer or when visibly dirty. For foam filters, wash with mild soap, rinse thoroughly, and allow to dry. Paper filters should be replaced, not cleaned, to maintain effectiveness. Neglecting air filter maintenance can lead to poor engine performance, reduced fuel efficiency, or even engine damage. Always refer to the manual for specific instructions tailored to your engine type. Regular air filter maintenance is key to prolonging engine life and ensuring reliable operation.

6.4 Spark Plug Maintenance

Spark plugs are essential for proper engine ignition. Regular maintenance ensures reliable engine performance. Inspect spark plugs every 100-200 hours of use or as recommended by the manufacturer. Remove the spark plug using a spark plug socket, taking care not to damage the threads; Check for wear, fouling, or excessive gap. Clean plugs with a wire brush and re-gap if necessary, using a gap gauge. Replace worn or damaged plugs with the correct type specified in the manual. Proper installation ensures a tight seal to prevent leakage. Regular spark plug maintenance improves fuel efficiency, reduces emissions, and enhances overall engine operation.

Engine Repair Procedures

Engine repair involves systematic steps to diagnose and fix issues. Always follow manufacturer guidelines for disassembly, inspection, and reassembly. Use specialized tools to ensure accuracy and safety.

7.1 Rebuilding the Engine

Rebuilding an engine involves a step-by-step process to restore it to optimal performance. Begin by thoroughly cleaning the workspace and gathering all necessary tools and parts. Disassemble the engine block, carefully labeling each component for reassembly. Inspect and replace worn or damaged parts, such as piston rings, bearings, and valves. Rebuild the cylinder head and ensure proper alignment of internal components; Apply lubricants and sealants as specified. Reassemble the engine in the reverse order of disassembly, using a torque wrench for precise bolt tightening. Refer to the service manual for specific torque values and procedures to guarantee accuracy and reliability.

7.2 Replacing Engine Components

Replacing engine components requires careful planning and precision to ensure proper functionality. Identify the faulty part using diagnostic techniques or manual inspection. Purchase replacement components from trusted suppliers or manufacturers. Disconnect power sources and ensure the engine is cool before starting. Use appropriate tools to remove the faulty part, taking care not to damage surrounding components. Install the new part by following the manufacturer’s instructions or service manual guidelines. Tighten bolts and connections securely, adhering to specified torque values. Test the engine to verify the repair and ensure smooth operation. Always prioritize safety and avoid shortcuts to prevent further damage or malfunctions.

7.3 Tuning and Adjusting Engine Performance

Tuning and adjusting small engine performance involves optimizing its operation for efficiency and power. Start by adjusting the carburetor to ensure the proper air-fuel mixture, often done using the idle and main jets. Check and set the ignition timing according to the manufacturer’s specifications. Diagnose issues like misfires or rough running by inspecting spark plugs and testing compression. Adjust valve clearances if necessary and ensure the throttle and governor systems are functioning correctly. Fine-tune the engine under load to achieve smooth operation. Always refer to the service manual for specific adjustments and procedures to avoid damaging the engine or compromising performance.

Specialized Repair Topics

This section covers advanced repair techniques for specific engine types, including two-stroke, diesel, and emissions systems, providing detailed guidance for complex scenarios and unique requirements;

8.1 Repairing Two-Stroke Engines

Repairing two-stroke engines requires attention to their unique design and operation. Key areas to focus on include the combustion chamber, piston, and crankcase. Carbon buildup is common, so cleaning these components is essential. Additionally, the cylinder’s port timing must be precise to ensure proper fuel-air mixture. Always use the correct oil-to-fuel ratio to prevent damage. Specialized tools, like a piston ring compressor, are often needed. Inspect the exhaust system for blockages, as this can significantly affect performance. Refer to the manufacturer’s manual for specific torque specs and procedures. Proper diagnostic tools and a clean workspace are crucial for successful repairs.

8.2 Diesel Engine Repair Considerations

Diesel engine repair requires a focus on compression ignition systems and fuel injection components. Common issues include fuel contamination, faulty injectors, and worn piston rings. Always use high-quality fuel to prevent sediment buildup. Air intake systems must be clean to avoid engine overheating. Inspect glow plugs for proper function, as they are essential for cold starts. Troubleshooting diesel engines often involves specialized tools like compression testers. Proper ventilation is critical due to exhaust fumes. Consult the manufacturer’s manual for specific torque values and procedures. Regular maintenance, such as replacing fuel filters, is vital to ensure optimal performance and longevity of the engine.

8.3 Handling Emissions Control Systems

When working on emissions control systems, prioritize understanding components like catalytic converters, mufflers, and exhaust gas recirculation (EGR) systems. These systems reduce pollutants and ensure compliance with environmental regulations. Diagnostic steps include checking for blockages, testing oxygen sensors, and verifying exhaust system integrity. Use specialized tools like OBD-II scanners to identify emission-related fault codes. Always refer to the manufacturer’s guidelines for specific procedures. Proper handling of emissions systems prevents contamination and ensures reliable engine performance. Regular maintenance, such as inspecting and cleaning sensors, is essential to maintain efficiency and reduce emissions. Follow safety protocols when dealing with hazardous materials and exhaust gases.

Resources and References

Explore manufacturer service manuals, online repair guides, and tool suppliers for comprehensive support. These resources provide detailed instructions, diagrams, and parts information to aid in successful repairs.

9.1 Manufacturer Service Manuals

Manufacturer service manuals are essential resources for small engine repair. These official documents, created by engine manufacturers, provide detailed specifications, repair procedures, and diagnostic information for specific models. They include exploded diagrams, parts lists, and step-by-step instructions, ensuring accurate and safe repairs. Whether you’re working on a Briggs & Stratton, Honda, or Kohler engine, these manuals are tailored to the exact make and model, making them indispensable for technicians and DIYers alike. Always refer to the correct manual for your engine to avoid errors and ensure compliance with manufacturer recommendations. They are typically available as hard copies or downloadable PDFs online.

9.2 Online Databases and Repair Guides

Online databases and repair guides are invaluable for small engine repair, offering instant access to repair information, diagrams, and troubleshooting tips. Platforms like iFixit, AllData, and RepairPal provide detailed guides for various small engines, including lawn mowers, generators, and power tools. These resources often include step-by-step instructions, wiring diagrams, and error code explanations. Many databases allow users to search by engine model or symptom, streamlining the repair process. Additionally, forums and communities within these platforms offer peer-to-peer support and real-world solutions. Regular updates ensure the information stays current, making online databases a reliable and efficient tool for engine repair tasks.

9.3 Recommended Tools and Suppliers

For small engine repair, having the right tools is essential. Basic tools include wrenches, screwdrivers, pliers, and socket sets. Specialized tools like compression testers, carburetor cleaners, and spark testers are also crucial. Reputable suppliers such as Snap-on, Harbor Freight, and Amazon offer high-quality tools. Additionally, many manufacturers provide tool kits specifically designed for their engines. Always prioritize quality to ensure durability and performance. Online retailers often provide customer reviews, helping you make informed decisions. Investing in a well-rounded toolset will enhance your repair efficiency and effectiveness. Regularly maintaining and organizing your tools will also improve your overall repair experience.

Mastering small engine repair requires practice, patience, and continuous learning. Apply the skills and knowledge gained to maintain and repair engines effectively. Keep exploring and stay updated!

10.1 Summary of Key Concepts

This manual has covered essential aspects of small engine repair, including safety practices, tool selection, troubleshooting, and maintenance. Key concepts emphasize understanding engine components, diagnostic techniques, and routine servicing. Proper safety measures, such as wearing protective gear and following hazard warnings, are critical. Regular maintenance, like oil changes and air filter cleaning, ensures optimal performance. Troubleshooting common issues, like faulty spark plugs or fuel system problems, requires a systematic approach. By mastering these concepts and practicing repair techniques, users can confidently maintain and repair small engines, extending their lifespan and reliability. Continuous learning and hands-on experience are vital for proficiency.

10.2 Encouragement for Further Learning

Mastering small engine repair is a rewarding journey that requires continuous learning and practice. Encourage yourself to explore advanced topics, such as specialized tools and diagnostic software. Join online forums, workshops, or courses to deepen your understanding. Hands-on experience is invaluable, so apply your skills to various projects. Stay updated with industry trends and manufacturer guidelines to expand your expertise. Remember, every repair is an opportunity to learn and improve. Embrace challenges and seek mentorship to refine your techniques. With dedication, you’ll become proficient in diagnosing and fixing complex issues, ensuring your small engines run efficiently for years to come.

10.3 Final Tips for Successful Repairs

For successful small engine repairs, patience and attention to detail are crucial. Always follow the manual’s instructions and double-check your work. Stay organized by labeling parts and tools to avoid misplacement. Keep a clean workspace to prevent contamination and ensure safety. Regularly test components after repairs to confirm functionality. Document your progress for future reference and to track improvements. Learning from each repair fosters skill development. By adhering to these practices, you’ll achieve professional-level results and extend the life of your engine. Remember, consistent effort and dedication will yield lasting success in small engine maintenance and repair.